In the entire tiny-house movement, one tiny house stands out: it sounds the kookiest, but is the most likely to transform your world some day. Called the Mushroom Tiny House, it’s now growing in the upstate New York plant of Ecovative Design. (Rhymes with “innovative,” not with “evocative.”)

As you can see in the picture, it has inner and outer sheathing of tongue-and-groove wood. Within those walls, Ecovative is culturing fungi. On purpose. Mixed with moist ground-up corn stalks or other agricultural waste that serves as its food, this fungal mycelium takes just a few days to fill the space, at which point it will be dried out and killed. It will provide fire-resistant, vapor-permeable insulation, while also being so strong, and adhering to the wood so firmly, that no studs are needed.

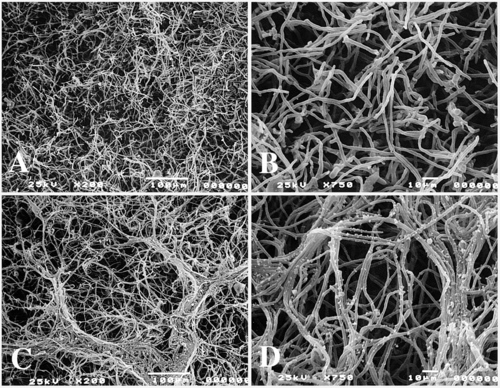

(What is mycelium? It’s the “body” of a mushroom fungus, living year-round in the soil or other substrate, whereas the mushroom itself is just a temporary spore-disseminating organ. Mycelium comprises miles and miles of fast-growing, tiny, tangled, fibrous tubes each just one cell thick.)

Ecovative has been getting media attention this month focused mainly on their smaller products. There’s a New Yorker piece, a fun read about two college students who took an Inventor’s Studio class, and their professor who took their idea too seriously to let them drop it. It all started with the one who grew up working on his dad’s sugar maple farm in Vermont…

Now, that boy has taken on the grand mission “to eliminate disposable plastics.” It gets even grander: “We had the Bronze Age, we had the Iron Age, fifty years ago the Plastics Age. We’re trying to introduce a new polymer to the world … which is literally grown…”

So far, Ecovative’s main market niche is packing material, but their initial business plan was to make rigid panel insulation for buildings. To win €500,000 and a prestigious international prize in 2009, they promised to start building structural insulated panels (SIPs) in 2010.

It didn’t happen. Co-founder Eben Bayer told The Business Review this year that that “was a difficult first product and it would have been a ‘heavy lift’ to penetrate the building materials market.” They switched to packing materials for their first big market push, while also experimenting in all directions: Dell is shipping computers using molded mycelium corner pieces; Puma is making a biodegradable shoe with them; Patagonia is making surfboards with mycelium cores; a race car has their mycelium for protective paneling.

This year, they are ready to get back into building materials. Mushroom Tiny House is their opening showpiece. I don’t know if anyone’s going to actually finish and furnish it, let alone live in it, but it’s a good demo for SIP manufacture.

Ecovative claims that, compared to plastic foams, mycelium fill would be equal in cost, less toxic, stronger, more soundproof, more flameproof, more vapor-permeable, less insulating per thickness, but of course far, far better ecologically—in its global warming potential, and also at end-of-life. When used in SIPs, its adhesion to the wood panels avoids the use of glues, a toxic ingredient in many plastic-filled SIPs. For flameproof, watch this clip from CSI New York. (Talk about product placement! and the product was still in the future.)

What about down sides?

1. “Less insulating” was the one drawback I slipped into that list just above. Ecovative’s panels will be a little thicker and almost twice as heavy, for a given insulation value.

2. You may be nervous about fungi growing in your walls. Ecovative dries and then bakes its products to make sure they are sterile, and then treats them with, get this, anti-fungal agents.

3. While we may feel guilty about building houses with plastics that take forever to biodegrade, we may experience qualms over living within walls that can biodegrade rapidly. I look forward to hearing what they have to say about “in the event that your insulation gets wet.”

In the near term, if you get a shipment packed in something that looks kinda like styrofoam but dingy and/or smeary in color, and on close inspection doesn’t look quite like anything you ever saw before, just whoop, “ It’s a fungus!” You can toss it in your garden and watch it turn into soil.