Researchers at Stanford University say a breakthrough in nanotechnology could lead to inexpensive solar window coatings. The secret is in a new method used to fabricate meshes made from nanowires.

Nanowires are one-dimensional strips of semiconductor materials only about one-thousandth the width of a human hair. One of the perceived advantages of solar cells made from nanowires is that they can be manufactured from some of the most abundant materials on Earth, rather than highly processed silicon.

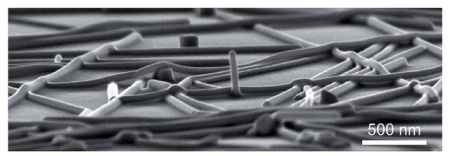

A research team at Stanford believes that meshes made of criss-crossed metal nanowires that conduct electricity could be a common material in everything from thin-film solar cells and LEDs to touch-screens and video displays. But nanowire meshes pose a major engineering challenge: in order to weld the nanowires together, the materials must be subjected to high heat, which can damage them in the process.

To overcome that hurdle, the team has come up with a new way to weld together the mesh using plasmonics. Plasmons are density waves of electrons, created when light hits the surface of a metal under precise circumstances. In a paper published in the journal Nature Materials, the team recently demonstrated a promising new nanowire welding technique that fuses the wires with a simple blast of light.

“When two nanowires lie criss-crossed, we know that light will generate plasmon waves at the place where the two nanowires meet, creating a hot spot,” said Mark Brongersma, an associate professor of materials science engineering at Stanford, and co-author of the study. “The beauty is that the hot spots exist only when the nanowires touch, not after they have fused. [The process] is self-limiting.” This method allows the rest of the wires and the underlying material to remain unaffected. As a result, it enables engineers to heat the material with more precision, control, speed and energy efficiency.

To demonstrate the possibilities presented by their discovery, the researchers applied their nanowire mesh onto a piece of Saran wrap, and dried it. After illumination, what was left was an ultra-thin layer of welded nanowires, that was virtually transparent. After balling the mesh up like a piece of paper and unfurling it; the material retained its electrical properties. According to another lead author in the study; this would never have been possible with previous welding techniques using a hotplate. The Saran wrap would have melted before the silver, destroying the device.

In addition to making it easier to produce stronger and better performing nanowire meshes, the researchers say that the new technique could enable the integration of mesh electrodes into flexible or transparent plastics and polymers. The research was supported by the Center for Advanced Molecular Photovoltaics (CAMP) at Stanford University, and funded by King Abdullah University of Science and Technology (KAUST).