Oregon got a big chunk of the money it needs to retain its leadership position in wave energy development in the United States yesterday when the U.S. Department of Energy confirmed a $4 million grant to help build the Pacific Marine Energy Center, a grid-connected device test site.

The grant, which will need to be matched by raised funds, was announced at the Ocean Renewable Energy Conference in Portland, where industry players from around the world are gathered this week.

The need for a test site was highlighted by the disparate concepts under discussion at the conference. This isn’t the wind industry before its big boom a decade ago, when there was no question about what technology would be employed as more wind farms popped up; with wave, there are an endless number of schemes at varying stages of development. Who knows what will work in the long run?

Start with the two devices that have been in the news in the past month in Oregon: the WET-NZ, a joint New Zealand-Oregon project, and the PowerBuoy, from New Jersey-based Ocean Power Technologies.

The WET-NZ has been undergoing testing in the waters off the coast at Newport, Ore., connected to a mobile test pod run by the Northwest National Renewable Marine Energy Center out of Oregon State University, while the PowerBuoy is being readied for deployment off Reedsport, Ore., in what is licensed to eventually become the first grid-connected wave array in the country.

These devices share similarities, and yet they’re also very different. Both are what are known as point-absorbers, moored, floating structures that mostly are underwater put pop above the surface. They take advantage of components that, driven by the waves, move relative to each other. But the PowerBuoy moves up and down somewhat like a giant piston, and uses direct-drive mechanics to generate power. WET-NZ’s float rotates 360 degrees, and the device uses hydraulics to convert the rotation to electricity.

As different as those two devices are from each other, others devices intended to one day send power onto electrical grids hardly resemble either one.

M3 Wave Energy Systems is a Corvallis, Ore., company started by Mike Morrow, an OSU grad. (At the conference, Morrow showed a picture dating back to his student days, in 1991, when he made the first model of the device he’s pursuing today. Among the implements he used to build the model that he “tested” in what looked like a large home fish tank: a couple of milk crates, plastic bags from the school cafeteria and plastic Dairy Queen spoons.)

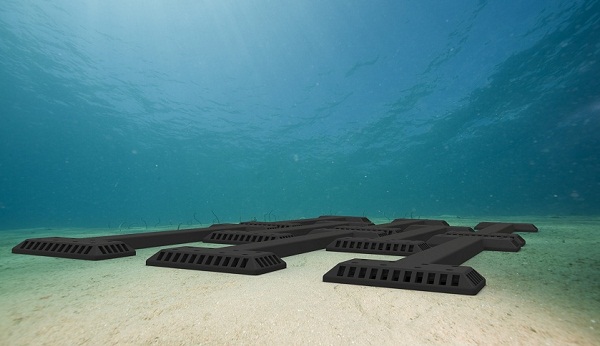

M3, if it makes it into the ocean, is one wave energy device you won’t see. It sits on the ocean floor. That makes it a possible winner aesthetically, and it’s a feature that could yield practical benefits, minimizing the device’s impact on commercial fishing and recreational users.

The device, which has been tested at one-sixth scale, works by taking advantage of underwater pressure changes caused by waves. Those pressure changes deflate an air bladder at one end of the device, pushing air through to a bladder at the other end of the device. As the wave rolls along, the action is reversed, sending air in the other direction. All the while, the moving air is turning a turbine placed in a chute between the two bladders. You might say the M3 wave energy converter is a wind energy device, using wind caused by waves — a neat switch on the fact that waves are caused by wind.

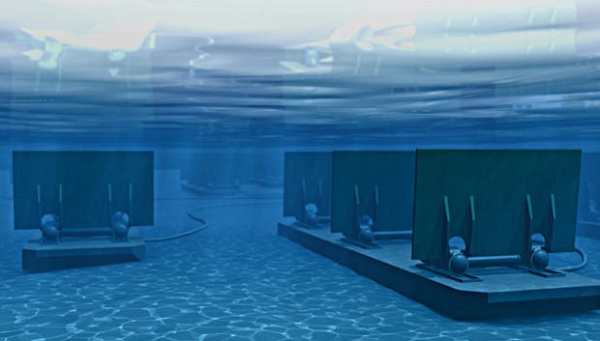

Another device: Tomasz Mucha of AW-Energy talked about the WaveRoller, another in the “submerged wave energy converter” category, like the M3 device – but looking and operating nothing like it. The WaveRoller consists of giant flaps, which are driven back and forth by the waves. In an earlier iteration, the device pumped water ashore for power generation, but a version now undergoing testing off Portugal has a combination hydraulic motor/generator as part of the ocean-floor device.

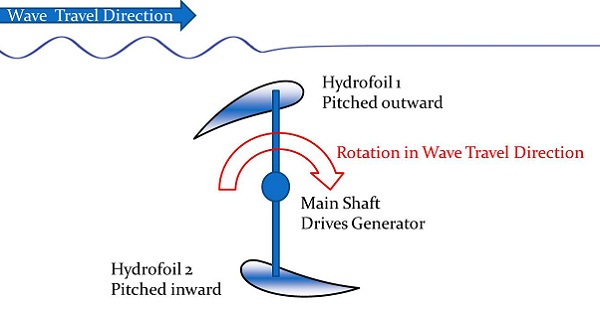

Atargis Energy is also looking to operate underwater, with a machine that looks a little like a vertical-axis wind turbine turned on its side. A key to the Cycloidal Wave Energy Converter (CycWEC) is that it can be “tuned” to the phases of the incoming waves, with the blade pitch adjusting throughout the revolution in order to extract as much energy as possible — a vastly higher percentage of the wave’s energy than typical devices, chief technology officer Stefan Siegel told the conference.

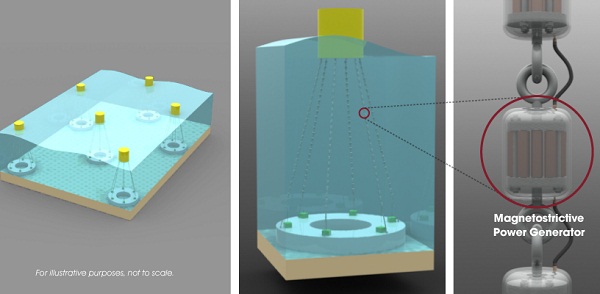

As if this diversity of concepts wasn’t enough, Rahul Shendure, CEO of Utah-based Oscilla Power, was in Portland to offer something completely different. Oscilla’s technology is based on using reverse magnetostriction. (Reverse what?) Turns out there are certain materials that undergo changes in their magnetic field when a load is placed on them. Since changes in magnetic fields can create a current, this opens up the opportunity of using waves to drive the reserve magnetostriction process.

The key to making this viable, Shendure said, was finding ferromagnetic materials that were neither expensive nor rare. Shendure says they’ve done that with iron and aluminum, and they call their patented technology iMEC.

The chief benefit of this concept: simplicity (which translates to “cost,” in several ways). The device would have no moving parts. A simple buoy is tethered to the ocean floor by mooring lines that uses the iMEC-enabled power generators. All it takes is the continuous motion of the ocean to activate the generators.

Which of these wave technologies — or any of the others being tested around the world — will win out is anybody’s guess at this point. Everyone knows that the winner or winners will be the ones with the lowest possible levelized cost of energy (the initial development and construction costs, plus operation and maintenance costs over the usage period). The battle is on.