The research team from MIT that gave the world the “artificial leaf” – the solar cell that could turn sunlight directly into a chemical fuel – is back, trying to model a device that can become a commercial reality while relying on our old (and not so pricey) solar friend crystalline silicon.

A new paper by the scientists, in the Proceedings of the National Academy of Sciences, doesn’t advertise itself as having nailed down the challenge. Instead, it delves deeper into the nuts-and-bolts of the technology in order to provide a roadmap to a “practical, inexpensive and commercially viable prototype,” MIT said.

“What’s significant is that this paper really describes all this technology that is known, and what to expect if we put it all together,” Casandra Cox, one of the co-authors, said in a statement. “It points out all the challenges, and then you can experimentally address each challenge separately.”

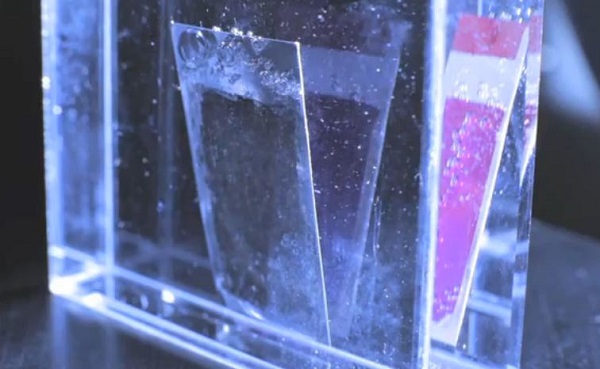

As we reported back in the fall of 2011, the artificial leaf concept consists of a silicon solar cell with different catalytic materials bonded to each side that allows it to split a water molecule into oxygen and hydrogen — a liquid fuel source.

This was tantalizing news when it appeared, raising the prospect of a new sort of storage mechanism for energy produced from solar. Problem was, while the researchers had provided proof of concept, their device’s lackluster efficiency – it turned just 4.7 percent of the sunlight in received into fuel – was woeful.

In trying to model a way to boost that efficiency without breaking the bank, the scientists focused on these areas: the architecture of the solar cell; the material; and matching that cell with the right catalyst.

There was a readily apparent way to up that efficiency – using multijunction solar cells – but, alas, “multijunction devices are costly,” the researchers wrote in their paper. “Thus, single-junction devices with higher SFEs (solar-to-fuel efficiencies) would be preferred.”

They wanted to make it work using crystalline silicon cells, “due to its lower cost and overwhelming market advantage” — even though they knew a single silicon junction couldn’t muster the juice to split water and produce hydrogen, the fuel they were after.

A potential path around this issue: pairing multiple solar cells in series. “Whereas a single absorber is often unable to generate sufficient voltage to drive water splitting, arranging solar cells in series can increase voltage and produce higher SFE,” the paper reported.

In the end, the researchers demonstrated a model with an efficiency limit of 16 percent using conventional silicon solar cells and 18 percent with gallium arsenide.

MIT cite an expert not involved in the research, James Barber from Imperial College London, saying this easily beats the 10 percent that would be needed to make the technology viable. Next step, Barber said:

“(C)onstruct a working system which has a large surface area and operates with solar energy under open field conditions for a long period of time, as is done with the testing of solar cells.” If this can be achieved, he says, “the construction of robust and efficient solar-driven modules which produce hydrogen from water on a large industrial scale would have considerable impact on human society.”

Here’s video from MIT of the articial leaf “in action”: