Many insecticides and repellents are harmful, both for you and your family as well as the environment. Thankfully there is an easy eco-friendly solution that is safe for everyone: a solar bug zapper. Solar bug […]

Green Living

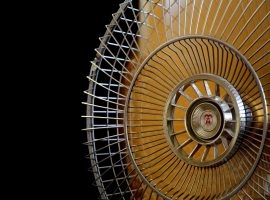

Best Solar Powered Fan

Cooling your home can be expensive, but solar powered fans offer a new way to help you stay comfortable without raising your electricity bill. After careful consideration of all the top solar fans on the […]

Best Solar Tiki Torches

Solar tiki torches are a great way to brighten up your yard and help you feel like you’re miles away on a beach somewhere. Plus, you don’t have to worry about them running up your […]

Best Electric Edgers

One detail that will greatly add to the beauty of your lawn as well as give your yard that finished professional look: perfectly edged sidewalks and garden beds. Choosing an electric edger is great for […]

Best Mini Solar Panels

When you think about solar power, what do you picture? If you’re like most people, you probably picture the large dark solar panels that can easily take up your entire roof. Although full home solar […]

Best Solar Laptop Charger

One of the best things about the modern world and all of our electronic devices is that we can work and communicate from just about anywhere, the only thing we need is power. If you […]

Best Robotic Lawn Mower

Pristine landscaping can be a serious hobby for some, but for most of us, it’s more of a chore. Constantly keeping the grass under control can take a lot of time and effort. Why not […]

Best Solar USB Charger

We all know how nerve-wracking it can be to try to use your phone only to find that the battery is running low. This is especially stressful when you are away from home and do […]

Best Reusable Straws

Let’s face it, even though many of us love straws, they aren’t necessary and they create a lot of unpleasant plastic waste. Many companies are discontinuing the use of plastic straws and the state of […]

Best Eco-Friendly Products for 2021

The importance of protecting our planet is permeating society and corporations, finally. And as a result, a number of innovative companies have been developing eco-friendly alternatives to everyday products or new products to help make […]

Best Bamboo Toothbrush

Did you know that approximately 1 billion toothbrushes are thrown away every year and that the majority of them are plastic? We can’t stop using toothbrushes, but we can decrease our excess plastic waste by […]

Best Fitness Trackers

Having a fitness tracker can be a great way to record your progress on your fitness journey as well as have some accountability for your daily activity levels. Fitness trackers can help you to keep […]

Best Glass Water Bottles

One of the best ways to stay hydrated is to carry water with you everywhere you go. Although there are a lot of options when it comes to reusable water bottles, the healthiest and most […]

Best Water Flow Meters

Water is an essential part of our everyday lives. Although we often use water without giving it much thought, there are times when keeping track of how much we use is extremely important. In times […]