What you really look for when picking out your favorite coffee is a roaster who has a super-efficient regenerative thermal oxider. Right?

OK, maybe not, but it’s technology like an RTO that can slash energy use in what is a very energy-intensive process. And artisanal coffee superstar Stumptown Coffee Roasters now has an RTO at its spanking new consolidated headquarters in Portland.

The Central Eastside facility, which the company was set to show off this morning with a ribbon cutting ceremony, pulls together Stumptown’s green coffee, roasting, production service, training and administrative operations. In a demonstration of how seriously Portland takes energy efficiency — or, perhaps, coffee — the local bicycle-riding, bow-tie-wearing Congressman as well as the state treasurer and the mayor were reportedly going to show up for the event.

But back to the RTO. Its function is to make sure the coffee roasting process doesn’t result in pollutants going into the air. We’re guessing coffee roasting is not in the same league as burning coal to produce electricity, but as one RTO manufacturer put it:

The roasting of coffee beans results in the emission of particulate matter, volatile organic compounds, organic acids, and natural gas combustion products. Green coffee beans contain a wide variety of chemical compounds including proteins, fats, sugars, dextrin, cellulose, caffeine, and organic acids. Some of these compounds volatize, oxidize, or decompose as part of the roasting process. Consequently, toxic compounds such as aldehydes (as formaldehyde), organic acids (as acetic acid) and acrolein are emitted as a result of the coffee roasting process.

In an article about Sumptown’s RTO, the Portland Business Journal explained that the company had previously used a high-temperature afterburner to break down the nasties produced in the roasting process.

An RTO gets the job done far more efficiently. In fact, using one will trim the amount of natural gas Stumptown uses in the process of roasting a couple of million pounds of beans each year by 25 percent, according to the Business Journal article.

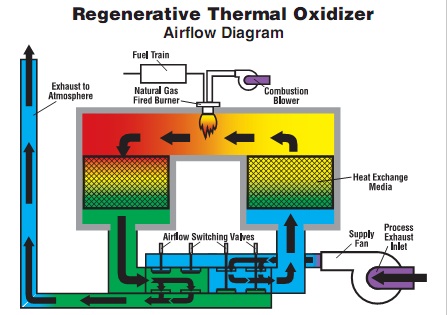

The RTO works by taking by scavenging every BTU of heat it can, and then putting it back to use. Ceramic materials (“heat exchange media” in the diagram below) continually collect and pass along heat as the dirty air and cleaned-up air circulates through the system. Very little heat is lost.

Stumptown’s estimate that it will cut its gas bill by a quarter seems like a sound number; Sara Lee reported that it used as regenerative thermal oxidizer at its coffee plant in the Netherlands to cut its gas use by 23 percent. “The RTO also reduces odor and other emissions to the plant’s surrounding area more efficiently than catalytic afterburners,” the company said.

Stumptown noted that the RTO was acquired “through significant support from Energy Trust of Oregon,” which is funded by a 3 percent “public purpose charge” from customers of Oregon’s two largest investor-owned utilities, Portland General Electric and Pacific Power.